Tech Tips

Choosing Materials for Chemical Container Labeling

In today’s market, there are many options for labeling chemical containers. These include vinyl, polyester, and polypropylene films. You can also choose from thermal transfer, laser, and UV inkjet printing.

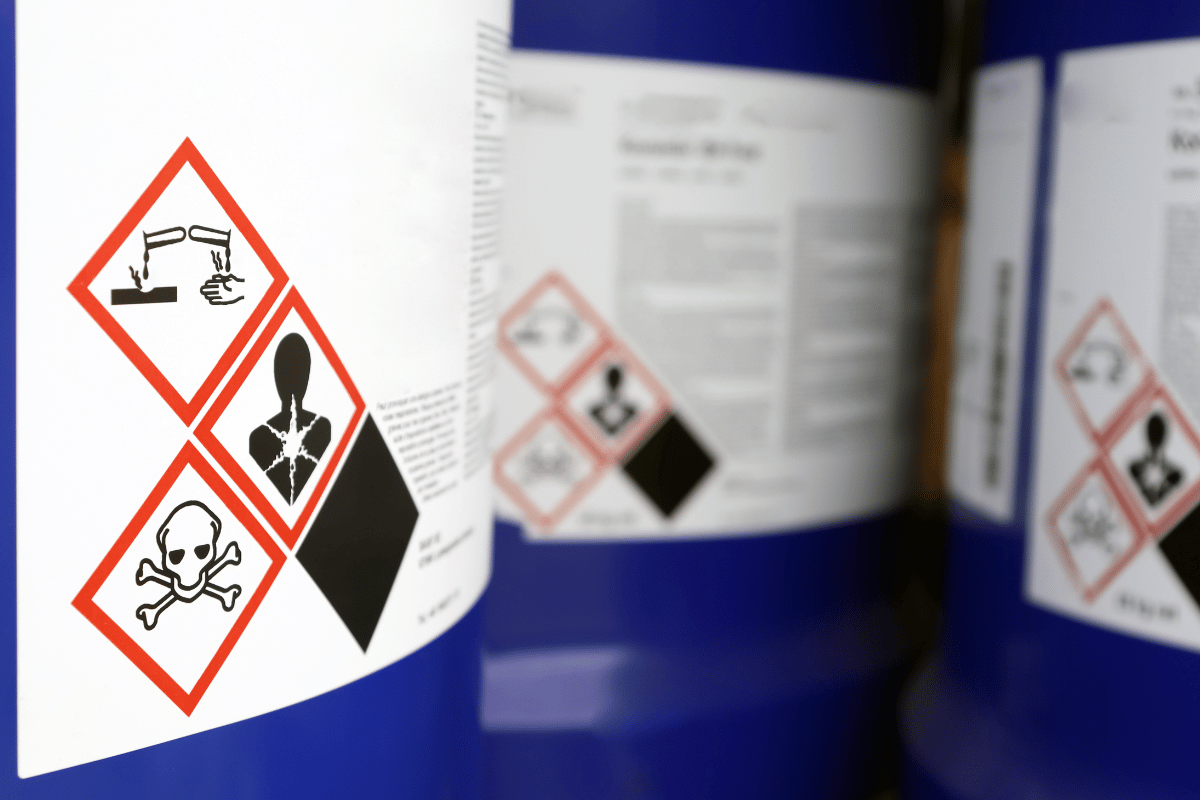

The purpose of these labels is to inform companies, employees, and the public about chemical hazards. This way, they can take steps to prevent exposure. They can also understand the possible health effects if exposure happens. The Globally Harmonized System of Classification and Labeling of Chemicals (GHS) requires that certain information appear on all container labels and recommends certification of label materials and inks under BS 5609.

Choosing the right materials for labeling your hazardous chemical containers can be confusing. We contacted experts in technology and marketing at ARMOR-IIMAK as well as our own market development specialists to provide insight on choosing materials for chemical container labeling.

Here’s what they had to say:

Durability requirements for chemical labeling

Durability of the film, the adhesive, and the inks is a prime consideration when choosing materials for chemical container labels. Under BS 5609, certification testing falls into two categories: Section 2 - durability of the film and adhesive in connection with exposure to salt water, temperature variations, weathering and sunlight; and Section 3 - durability of inks against abrasion.

The International Maritime Dangerous Goods Code requires BS 5609 certification for chemicals that will traverse the ocean. It is not required otherwise, however, the vast majority of end users will specify BS 5609 to help limit liability.

Printing considerations for chemical container labeling

Thermal transfer printing is the most widely tested print technology and remains the most reliable for chemical labeling applications. Resin ribbons are typically the ribbon-type of choice because of their superior durability.

However, wax/resin ribbons may be perfectly suitable depending on the exposures the labels may encounter, such as when containers won’t be exposed to the outdoors or handled aggressively, and spillage is not a concern. Ultimately, the Section 3 approval will determine which ribbons may be used.

Beyond durability of the inks, there are some additional considerations when choosing ribbons. GHS requires both black and red, but there are many grades of black ribbons and only limited choices for red.

While there are thermal transfer printers with dual color capabilities, they usually have the same heat setting for both colors, so it’s important that the ribbons have similar melt points. Otherwise, one or the other won’t transfer properly, leading to poor print quality.

Print speed is also a factor for optimizing print quality. Slower speeds require a lower temperature so as to avoid burning the film, which will result in wrinkle marks, as well as turning inks a grayish brown, both of which lead to poor barcode quality. Conversely, when running faster, you may need to elevate the temperature to ensure an adequate transfer of ink.

Films and adhesives for chemical container labeling

The appropriate choice of film and adhesive is dependent on several things.

Container material and surface

The surface energy of metal, cardboard, plastic, and glass is different. An adhesive that sticks well to one may not stick as well to another. If the container will be reused, it may be good to use an adhesive that can be removed later. This way, the end user can refurbish or reuse the container easily.

How filling the container affects label adhesion

Label adhesion can be impacted by the point at which filling occurs. If it will occur before labeling, there is a likelihood that labels will be exposed to the container contents. Polyesters (PET) tend to perform the best when exposed to caustic chemicals, but if cost is a factor, polypropylene (PP) may be a suitable alternative.

If the container is a plastic and the chemical going into it will be hot upon filling, however, the container may shrink on cooling, causing distortion or edge lift of a PET or PP label. In this case, vinyl may be preferred because it can expand and contract with the container.

Label exposure conditions

There are many adhesives in the labeling industry that are suitable for chemical container labeling. Choosing the right one is dependent on multiple factors, such as the various conditions to which the label could be exposed. These include the container contents, of course, but also weather, temperature extremes, UV rays, and salt water, if the container will be transported overseas.

For example, if labels will be applied at cold temperatures or be exposed to them, a softer adhesive is required for labels to adhere properly and remain adhered. For high temperatures, you need a firmer adhesive that still has some flexibility. This helps prevent piping and wrinkling.

GHS went into full effect in 2016, but non-compliant labels continue to exist, and the legal ramifications of a serious injury due to non-compliance could be significant. Furthermore, in the U.S., OSHA’s Hazard Communication Standard is aligned with GHS and BS 5609, opening companies up to possible liability if containers are not properly labeled.

There are many things to think about when choosing materials for chemical container labels. Suppliers who are well-versed in the application requirements can assist you in choosing label materials that will perform as expected, protect workers and the public, and limit liability.

Suggested products:

Flexcon® DrumCal™ for hazardous container labeling | Flexcon Vinyl Durable Label Material