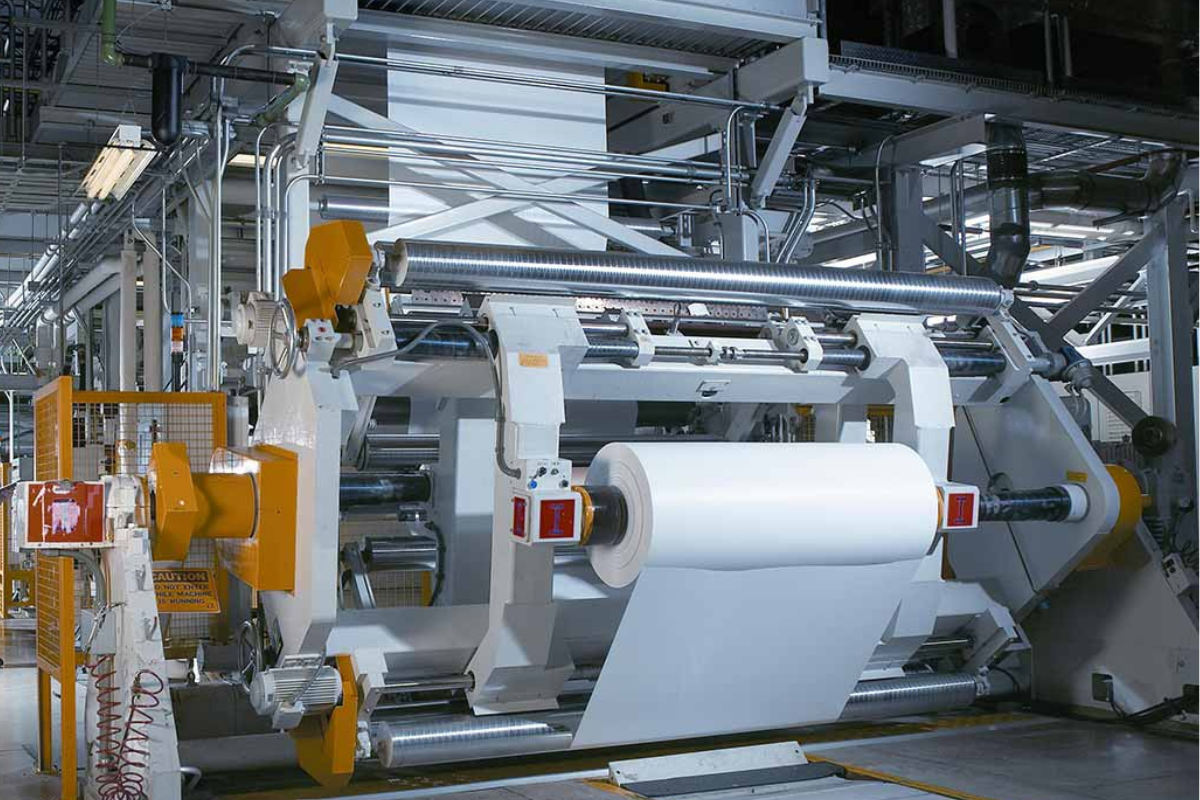

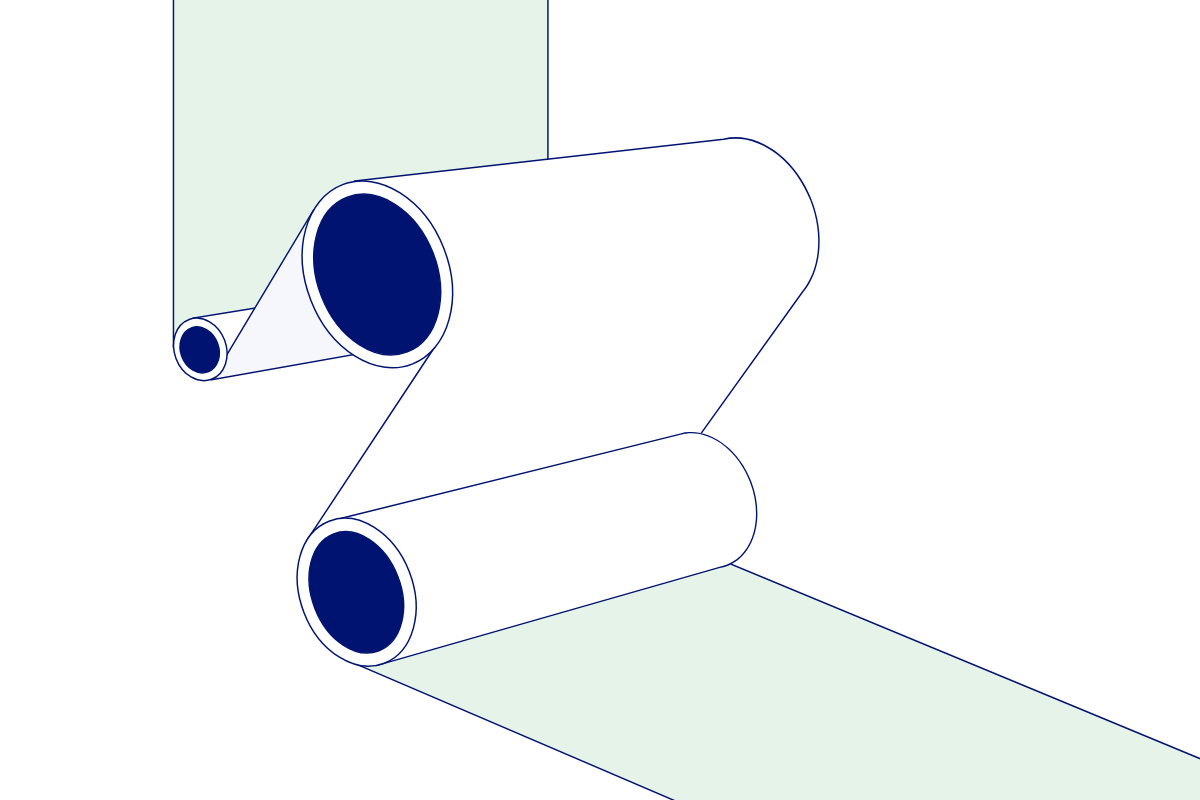

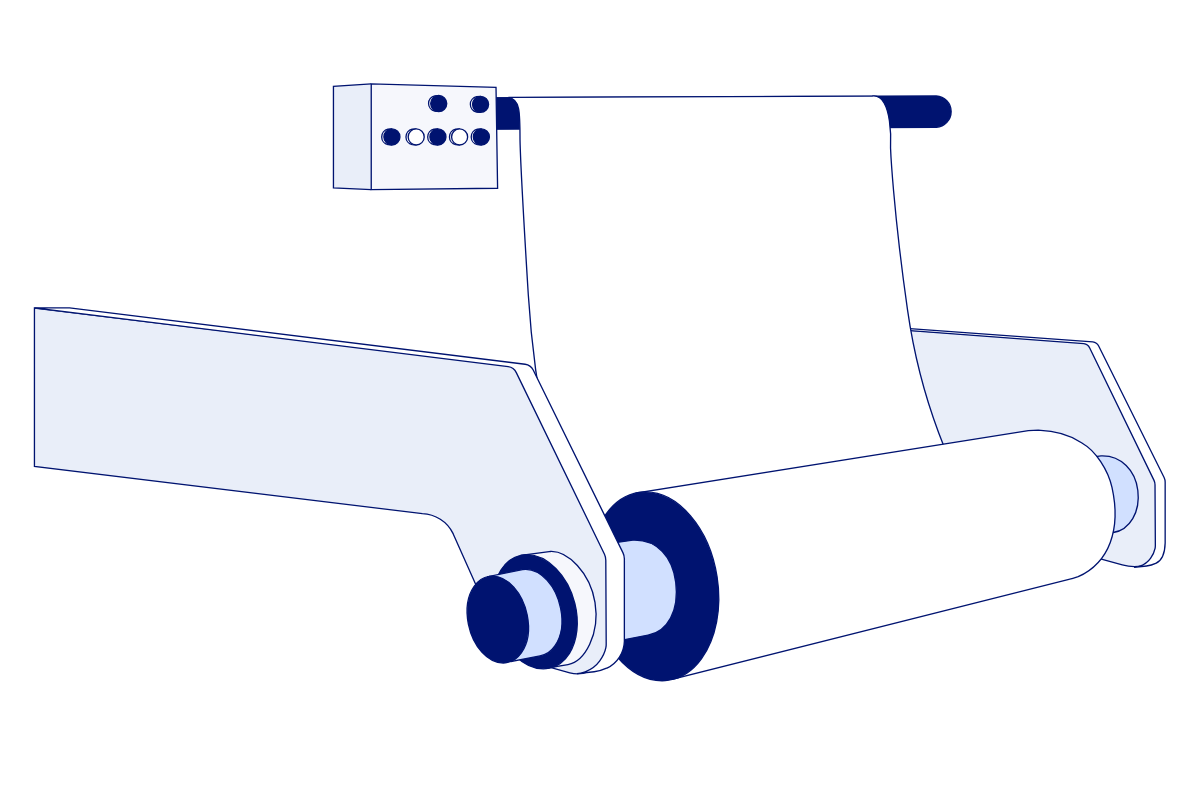

Zone Coating/Dry Edge

When you need certain areas of the film to be free of adhesive, the adhesive can be coated in lanes, leaving alternating lanes free of adhesive. If your need is to have rolls with the edges free of adhesive, it can then be slit within the adhesive-free lanes to provide dry-edge rolls to avoid blocking of the rolls and adhesive ooze during processing.