Tech Tips

Material Suitability Testing: A Crucial Element for Application Success

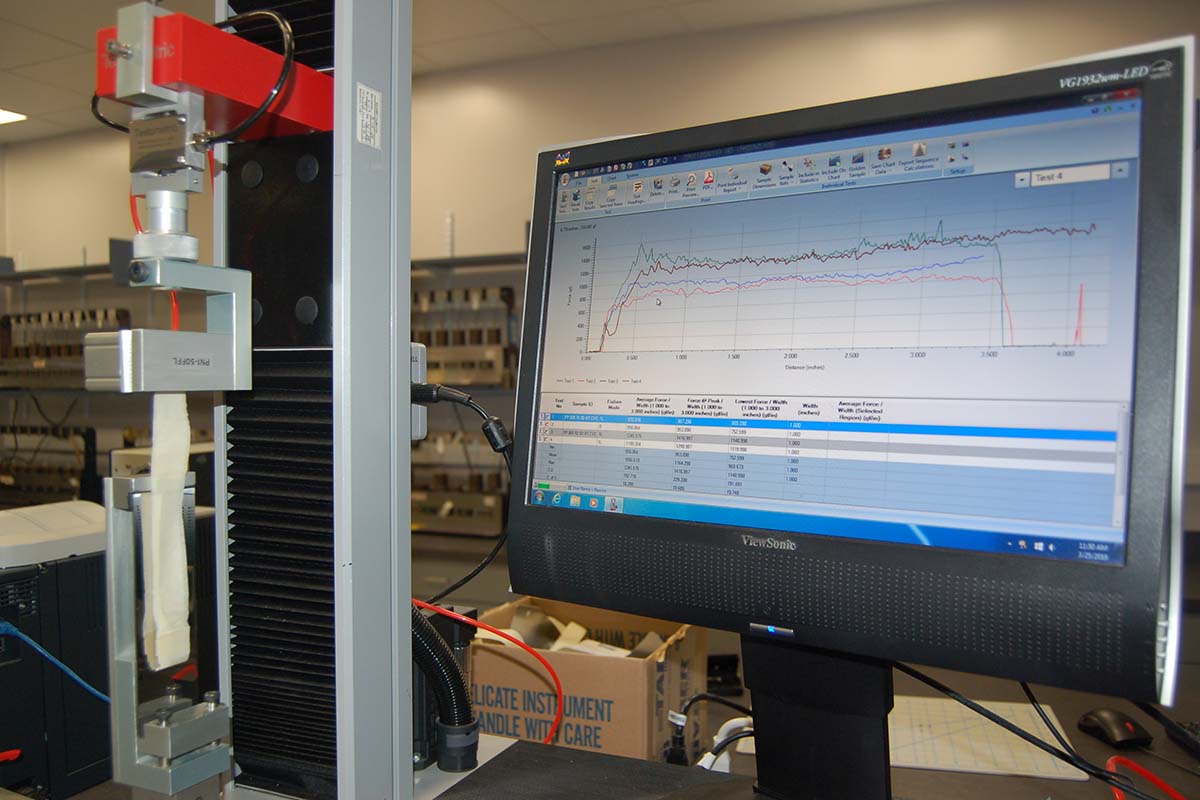

When it comes to choosing the right product for your application, there is no substitute for material suitability testing. As part of your material suitability testing protocol, you should test the adhesion of the product by applying it to the end-use application surface.

It is crucial that this process take place after you have selected the product that appears to best meet your needs, but before you move into full production. Material suitability testing may add a bit of extra time to the qualification process, but it can ultimately save time and money in the long run. That is why it should be an integral element of the material selection process.

Request a hand sample.

It is important to work closely with your customer to understand the circumstances under which the product is being used. Before making a final selection, customers should request a hand sample or sample roll of the product and adhere it to the intended surface.

The customer can then observe how the product performs for 24, 48 or even 72 hours to get a sense of how the end-use product will respond in real-world conditions. This will enable you to evaluate the results to feel confident it functions as expected.

Application surfaces that are challenging to bond to:

- Low energy surfaces such as those that are silicone treated or chemically treated for corrosion resistance, waxed or greasy, or printed polyethylene.

- Rough surfaces where surface contact is likely to be low, such as wood, metal, lacquered finishes, cork, foam, open weave fabrics, embossed finishes, and unglazed pottery.

- Moist or cold surfaces such as those caused by condensation, ice or deep freezing.

- Irregularly shaped surfaces such as glass vials, ampoules, or spirit miniatures where the label is applied to a convex surface of less than 25 mm in diameter.

- Dusty surfaces such as plaster and fiberglass.

- Surfaces which may be extensively exposed to the atmosphere, or submerged in salt or fresh water, or exposed to chemicals (resulting in eventual failure of the adhesive) such as steel drums.

Flexcon can provide you with hand samples at no cost to you. If, after testing the samples, you wish to do a short run as part of a more extensive material suitability test, you can order a sample roll of the material.

In the long run, material suitability testing can mean the difference between the success and failure of the application, and is more than worth the effort.