Tech Tips

How Vibration Damping Adhesives Work

Flexcon has been designing and manufacturing pressure-sensitive adhesive (PSA) containing composites for nearly 70 years. These products include materials for bumper stickers to the highly engineered PSAs used for sound and vibration damping. They can also bond to low surface energy materials like silicone rubber.

Vibration damping adhesives

Flexcon supplies engineered adhesives for use as the viscoelastic layer in constrained layer damping.

To understand how vibration damping adhesives work, we've outlined some of the technical aspects the adhesive material.

Viscoelastic material

Materials can change their state or phase with changes in temperature. Water, for example, at moderate temperatures is a “liquid.” When the temperature cools to 32ºF (0ºC), water freezes into ice. When you increase the temperature to 212ºF (100ºC), water boils into a “gas” (vapor).

Polymeric materials also undergo significant changes in their state with changes in temperature. While measurable, the changes in state may not be as clearly obvious as melting ice or boiling water.

People often use the term “melting point” or “melt flow” for some polymers. However, it may not accurately describe the polymer's property. This is especially true when pressure affects the polymer or when the polymer undergoes cross-linking (thermoset).

In general, polymers have a more complicated relationship to temperature. For example, unlike water, they are also sensitive to the rate of temperature change.

Given these facts, just what do polymers do? What are their changes in state with respect to temperature changes?

And how does all this relate to “vibration damping”?

What polymer transition states mean

Glassy Phase - The Glassy Phase is roughly equivalent to the solid phase in water. The polymer is at its hardest in this phase. It does not work well for sound damping in the Glassy Phase. The polymer tends to let noise pass through the vibrating structure.

Elastic Phase - When you heat a polymer, it transitions from its Glassy Phase to its Elastic Phase. We call the temperature at which this occurs “the glass transition temperature,” designated Tg. This phase marks the beginning of vibration damping.

Viscous Phase - This phase is still good for damping. However, as the temperature rises at a constant frequency, the ability to recover starts decreasing.

Polymers are more complex than simple materials like water. They behave differently when the temperature changes. Polymer response to changes in temperature can vary by the rate of change in temperature.

Simply stated, the faster the rate of temperature change, the higher the Glass Transition Temperature, or Tg.

If the change to a polymer is mechanical, like a vibration, the same rules apply.

The faster the change, or the higher the frequency, the higher the apparent Tg.

This phenomenon is familiar to everyone who has ever played with Silly Putty.

The Silly Putty effect

Roll the Silly Putty into a cigar shape, then hold it by the ends, and slowly draw it out. It seems as though we could stretch it forever or at least until our arms are at full extension.

However, when we pull the cigar quickly, in effect creating a “vibration,” the Silly Putty snaps like a piece of chalk. The higher the vibrational frequency, the more “solid” the polymer is at any given temperature. To keep the same thickness of a polymer when the vibrational frequency goes up, the temperature must also rise.

To measure vibration damping, we measure the Tg dynamically. This means we measure it at different frequencies and temperatures.

Damping potential: Loss factor and storage modulus

The most useful metrics in evaluating a polymer’s damping potential are its loss factor and storage modulus.

When a ball drops from a height, the ball deforms, then bounces back easily. The bounce-back (recovery) is a measure of how much of the impact energy the ball could store and release to bounce back. This is the “storage modulus.”

We call the difference between the starting height and the recovery height the “loss factor.” This shows how much energy the system lost as heat to the surrounding environment. The ratio of these two quantities is a useful measure of damping ability. We define the tan d (tan delta) as the ratio of the loss factor to the storage modulus.

One way to show how temperature and frequency interact is to run Tg tests at a set temperature. This process occurs over a range of vibrations. We then go to another temperature region and again evaluate the Tg as a function of changing frequency.

Please note that, from the polymer’s view, it does not matter whether someone conducts the test at a constant frequency. The temperature can vary, and then the cycle can repeat at another constant frequency. The temperature can change again, and so on. Thus, we see the limits on the use of viscoelastic liquid for vibration damping at a given frequency.

If the temperature of the polymer is too low, it may be in its Glassy state. If the polymer's temperature is too high, it may become extremely fluid. In this state, it might not have a strong enough storage modulus to recover.

Reduced frequency nomograms

Polymer chemists have used the “master curve” for a long time. This tool helps them show complex relationships clearly and effectively. The master curve shows how temperature and frequency relate to changes in Tg and vibration damping. They call it the "Reduced Frequency Nomogram."

Here we note that we chose a reference point to begin construction of the nomogram. You can start the nomogram at any point. However, it is best to choose a point near a key element. For example, select a point where the “loss factor” is close to 1 (101).

The nomogram shows that the Flexcon SA6000 series adhesive has good damping properties. It works well in temperatures from -180°F to -280°F.

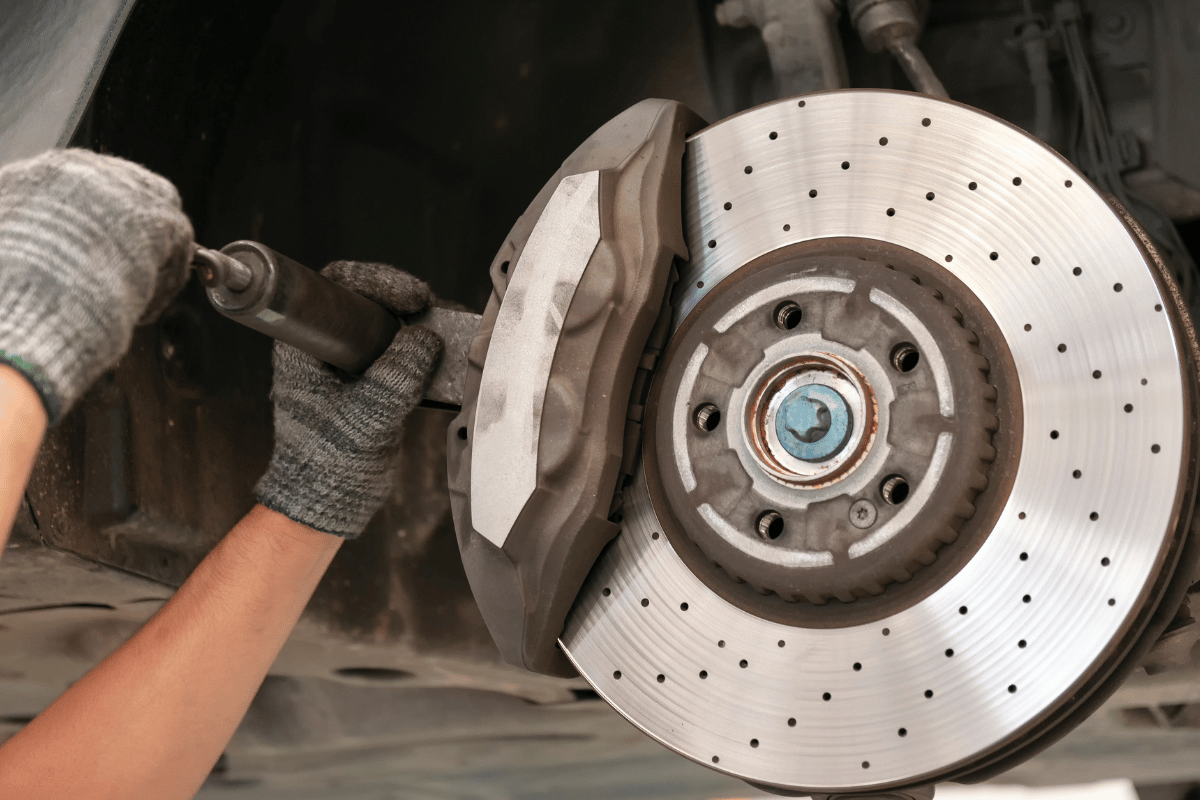

Furthermore, the frequency range is indicated as roughly 500-15000 cycles/sec (Hz). This turns out to be in a good range for certain disc brakes on cars. Indeed, manufacturers have used Flexcon silicone adhesives in this application for years.

Flexcon’s tacky silicone adhesives in the SA6000 Series offer the same pressure-sensitive features as traditional PS adhesives. However, they also work well in extremely low or high temperatures where acrylic adhesives fail.

Using viscoelastic materials into a vibration damping treatment

Measuring a polymer's properties is important. Creating its reduced frequency nomogram is also key.

These steps help define a damping treatment for noise and vibration issues. But we need one more step -- we must construct the actual device. By placing a viscoelastic layer between two more rigid layers, the composite forms a constrained layer damping system.

The constrained layer damping system uses the displacement/recovery of the viscoelastic material. The vibrational input is transmitted through the rigid constraining layer to the viscoelastic layer.

The change in this viscoelastic layer helps turn vibrational energy into thermal energy. This process is known as the loss factor. As the final stage in the cycle, the viscoelastic layer recovers, and is thus ready for the next vibration (storage modulus).

Flexcon has adhesives that can work with many different vibration and temperature combinations. There may not be one viscoelastic material for all frequency and temperature needs.

Flexcon can provide these adhesives in different formats. They can be in transfer tape, as part of a single-coated product, or in a double-coated design. The double-coated option uses an extra adhesive to bond two surfaces that do not stick well together.

Conclusion

Flexcon offers vibration damping adhesive solutions and technical expertise that benefit many industries, from aerospace to automotive to appliance. Our engineered PSAs cover a wide variety of application requirements. They include adhesives that:

- Can bond sound damping materials to the inner skin of aircraft or can be the noise reducing component itself

- Meet aerospace, medical, and security requirements

- Are designed to form a bond in sub-zero cold, or to maintain adhesion at temperatures in excess of 500ºF (260ºC)

- Bond to low surface energy substrates

- Resist “out gassing”

- Respond to low frequency AC

- Greatly resist dielectric breakdown

- Act as a thermal insulator, or facilitate heat transfer

- Can lift a fingerprint or leave a fingerprint on the substrate if removed.

- Can be cleanly (no residue) removed

- Can survive the strict requirements for LOCA (loss of coolant accident)

By working closely with OEM Design Engineers, Flexcon’s special PSA skills solve tough problems in noise and vibration control. Contact us for information on Flexcon’s vibration damping adhesives and materials.