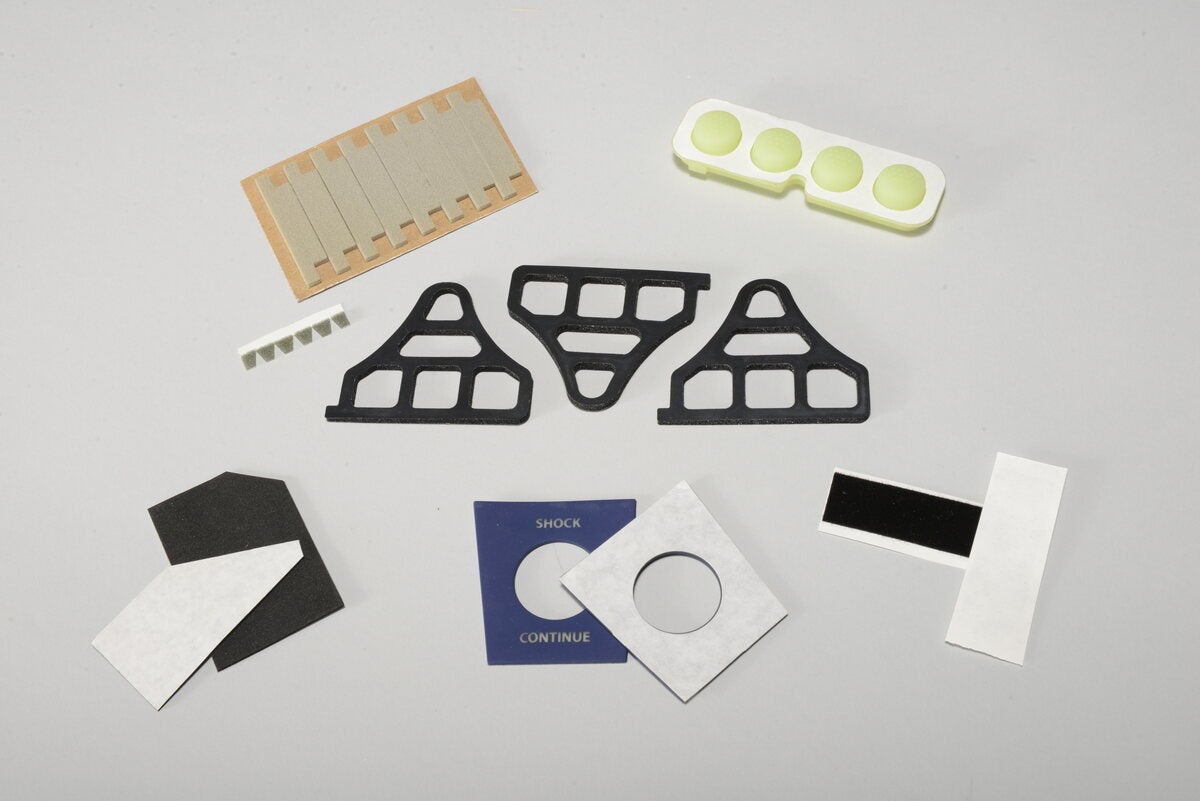

Ensure brand identity is never compromised with durable labeling substrates and mounting adhesives formulated to withstand the harshest of conditions. Get top-of-the-line label print quality as well as reliable cross-platform printability, from traditional methods like flexo, screen and thermal transfer to newer digital technologies like narrow-format UV inkjet. Flexcon durable label substrates provide a critical combination of durability, aesthetic appeal, and efficiency for brand identification.

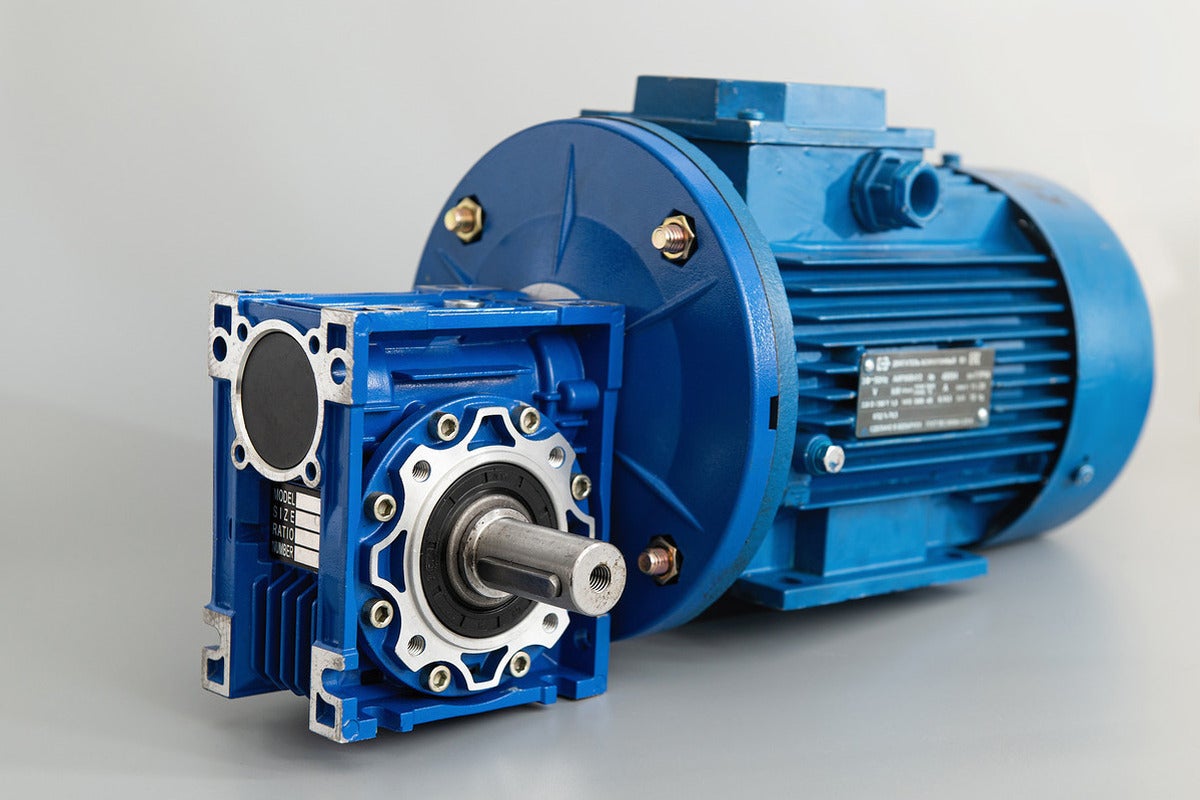

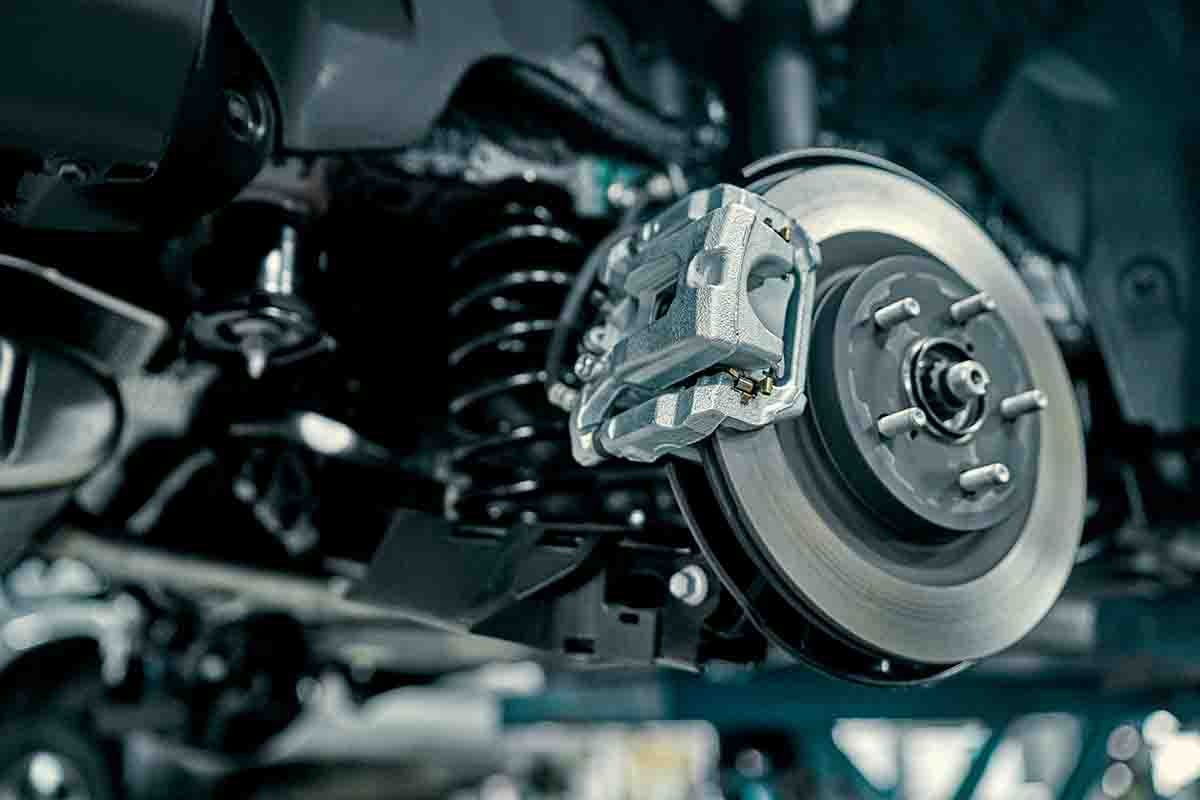

Industrial

Performance and Value in Demanding Environments

Feel confident in the performance of safety and identification labels in the most demanding environments. Achieve high performance with robust materials for a variety of industrial applications.