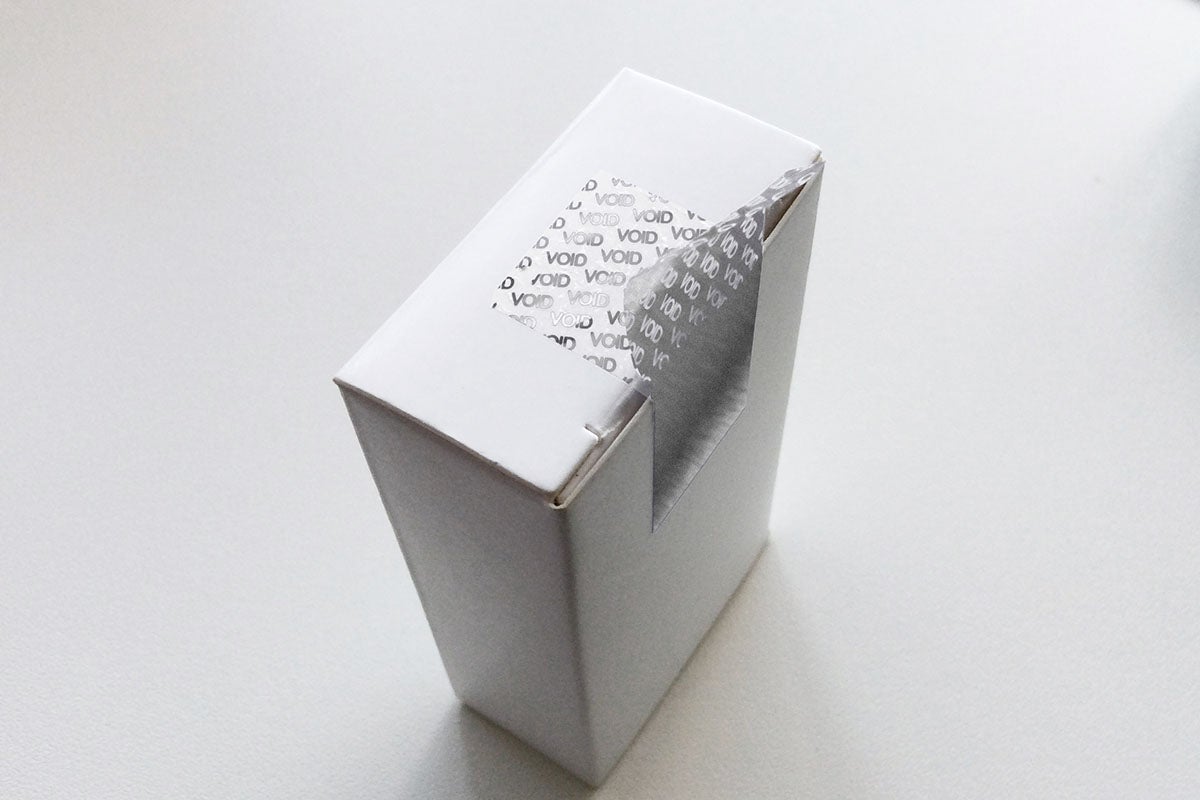

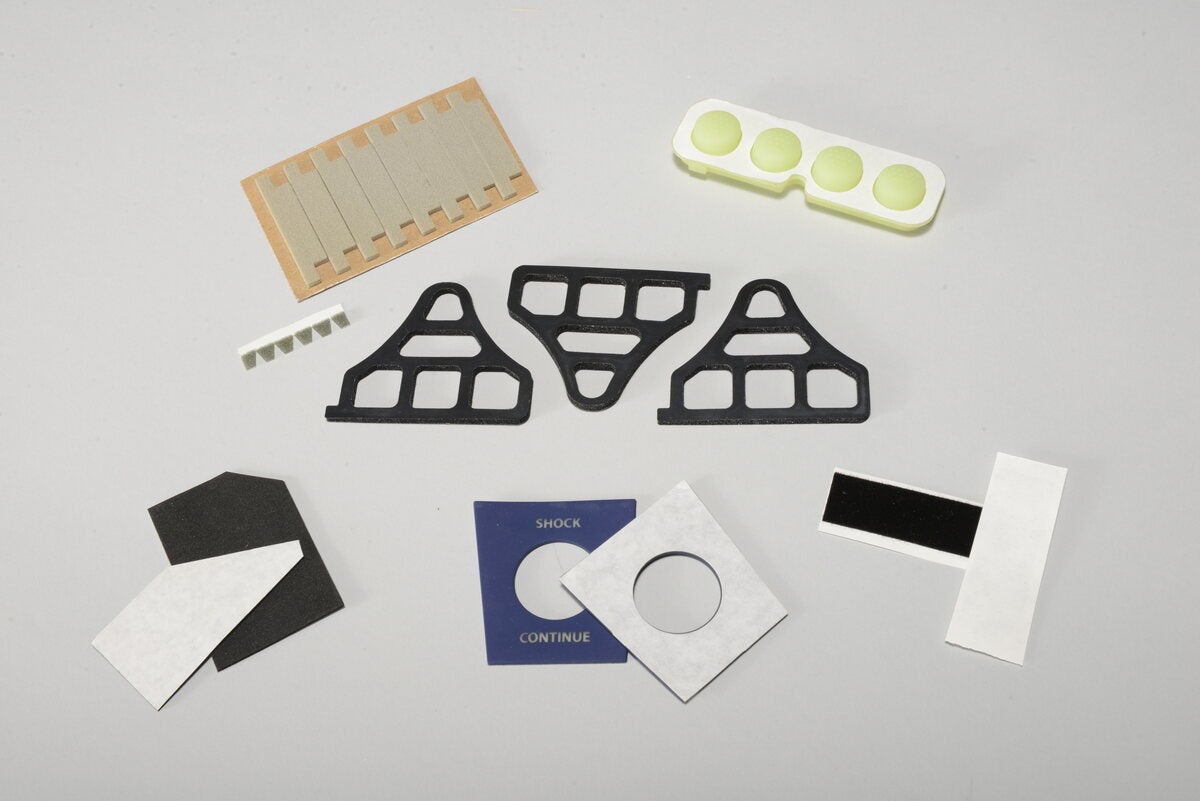

Ensure brand identity is never compromised with durable labeling substrates and mounting adhesives formulated to withstand the harshest of conditions. Get top-of-the-line label print quality as well as reliable cross-platform printability, from traditional methods like flexo, screen and thermal transfer to newer digital technologies like narrow-format UV inkjet. Flexcon durable label substrates provide a critical combination of durability, aesthetic appeal, and efficiency for brand identification.

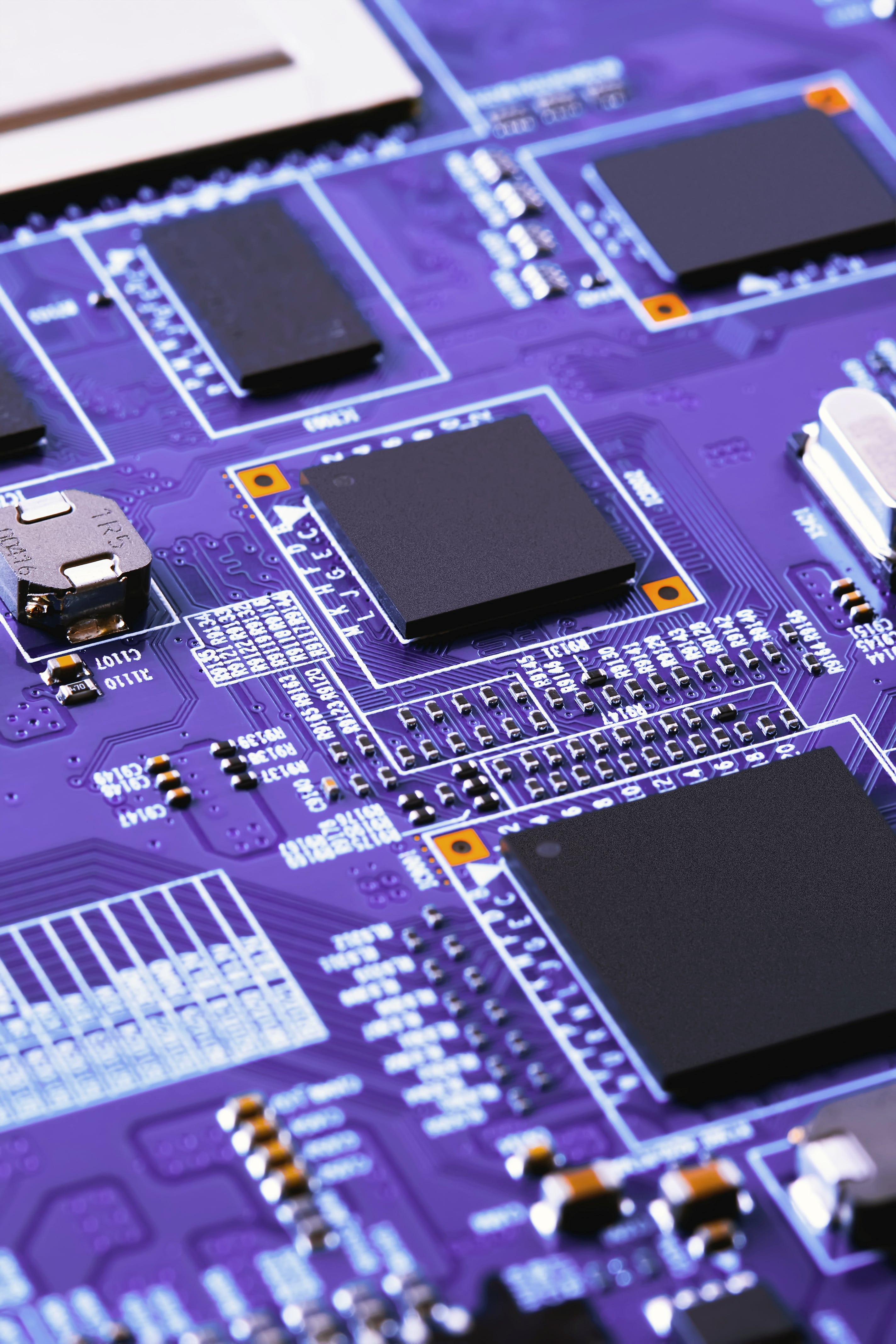

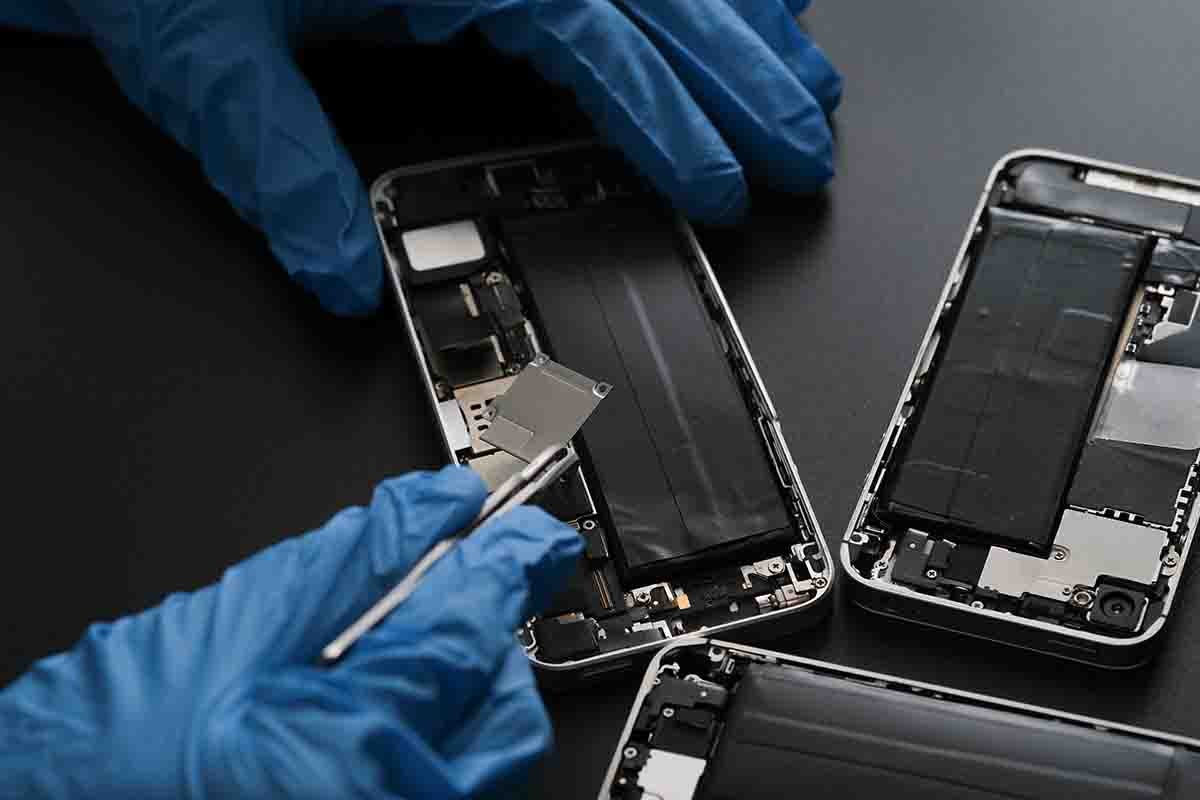

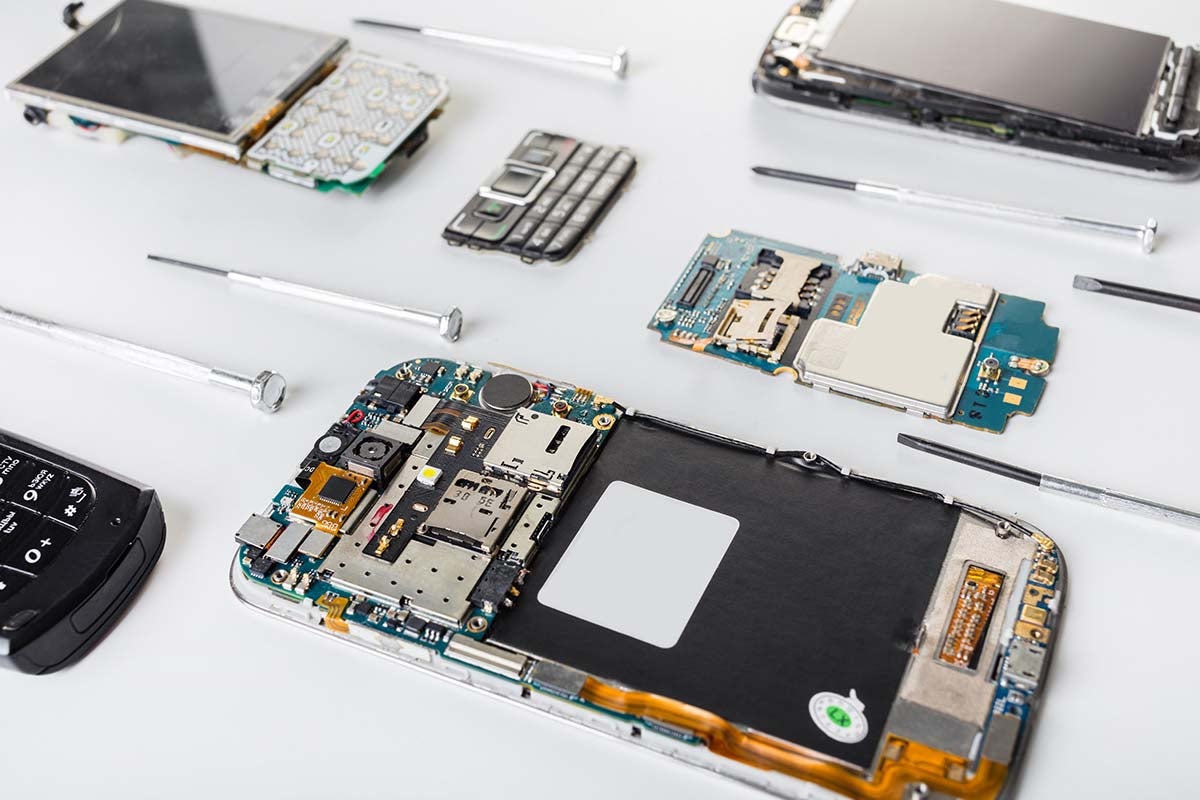

Electronics

Innovation and Performance for Tomorrow’s Technology

Ensure outstanding product functionality and performance for your electronics applications.